Dispensing applications

The industries for which Gemini Techniek supplies dispensing applications are:

Paint & coatings

GEMINI manufactures custom made dispensing machines for a wide range of applications in the paint and coatings industry that can combine product storage, dispensing, logistic systems and mixing / shaking. We have developed some typical dispensing machines (ColorKing RT, SegmentTank, FlexoKing CD, FlexoKing FT) that may suit your specific needs, but we also manufacture more conventional systems. All our dispensing machines are able to produce large batches and/or small batches in the range between approx. 1 kg. up to 3.000 kg.

Explosion-proof dispensing machines

The dispensing machines are also available in explosion proof execution and can dispense paints, coatings, base materials and additives all on one weighing scale or on multiple weighing scales to achieve a higher output. GEMINI systems are mainly used “in-plant”, but are also suitable for end users. Due to our long term experience in the paint & coatings industry, we have knowledge of dispensing very low viscosity products as well as high viscosity products.

Suitable products:

Ink

The ink industry requires the same dispensing technology as the paint & coatings industry. Especially inks that are being used for flexographic and gravure printing methods can be dispensed with the same dispensing machines as used in the paint & coatings industry. Ink manufacturers very often require “in-plant” dispensing machines to produce large batches of ink. At the same time these ink manufacturers can recommend smaller dispensing machines to their customers for preparing small batches that have to be added to the printers. GEMINI Techniek offers “in-plant” ink dispensing machines as well as more cost effective smaller dispensing machines (e.g. FlexoKing CD) for the end-users.

Chemicals

The chemical industry is similar to the paint & coatings industry. Recipe based dispensing of several components into a container. The chemical industry however may require higher safety measures. Keys or special tools, which are supplied for limiting access to areas or functions will provide a safe workplace

Textile

GEMINI can also offer dispensing systems for preparing and handling products for textile printing. Similar to the wallpaper industry, the transportation of containers/tubs (feed/discharge) can be automatised.

Our systems take into account both the need for speed and high accuracy dispensing of e.g. printing paste. Rework of return ink is also a possibility. We are able to offer you solutions that are not only accurate, but also cost effective. (e.g. plastic storage tanks or drums that have to be exchanged when empty)

Wallpaper & floor covering

The wallpaper & floorcovering industry has completely different requirements due to the products that are being used (e.g. PVC plastisols & pigment pastes). For this industry we have developed the GEMINI WPD-system that combines product storage, automatic transport of empty tubs, dispensing and mixing. Especially the mixing unit is unique in it’s kind. It has an automatic viscosity control system that has the ability to achieve the desired viscosity fully automatic. GEMINI has successfully applied its dispensing / mixing technology in this industry.

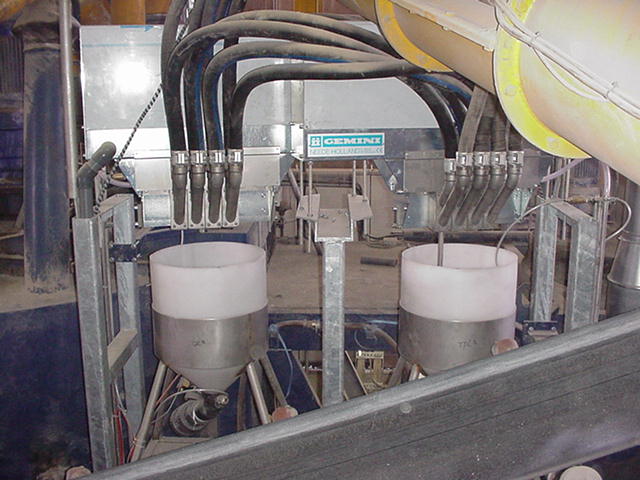

Concrete

The concrete industry is another market where GEMINI has successfully introduced dispensing machines for liquid pigment pastes. A number of concrete manufacturers of e.g. colored paving cubes are changing from powder pigments to liquid pigments because of cost and accuracy. With a higher accuracy, the number of colorants can be reduced in order to create the same color scheme.

The concrete industry further requires robust dispensing machines in order to withstand vibrations and dust. Thanks to special pump execution and valve design, the dispensing machines are very reliable and long lasting even with highly abrasive pigments.

Flavour & fragrances

This industry is characterised by dispensing a large number of components and is only a small step away from the conventional dispensing systems. The industry requires dispensing systems that are able to dispense small quantities with a very high accuracy. GEMINI can easily handle these needs by offering systems, where a large number of valves are placed in line and where a small container can be positioned under these valves.

Contact with Gemini Techniek

Would you like to know more about dosing or about another solution from Gemini Techniek? Contact us via telephone number +31 (0)53 428 3000, mail to info@gemini-techniek.com or fill in our contact form.

Dispensing machines

Discover here our extensive overview of different dispensing products and dispensing machines.