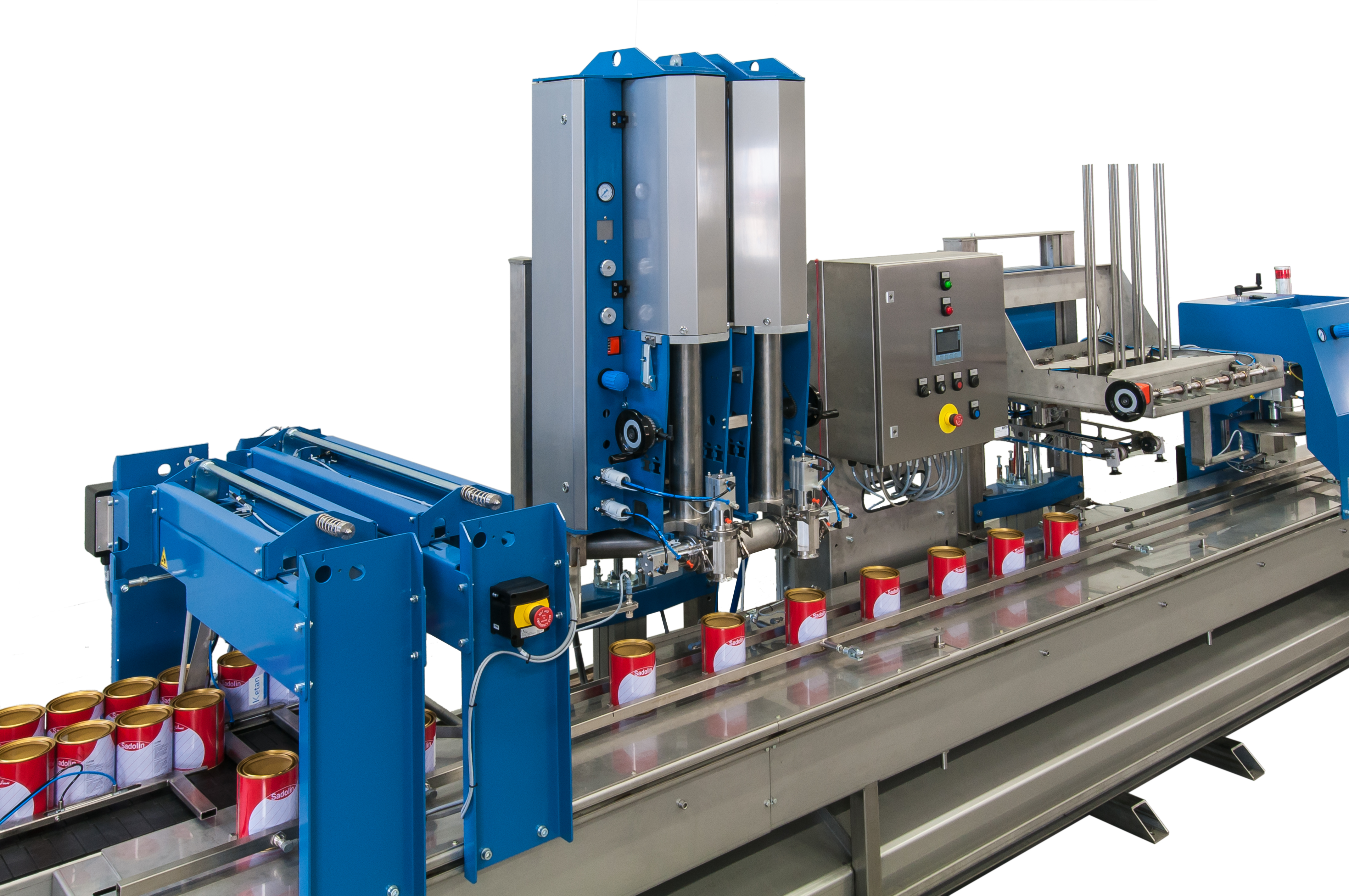

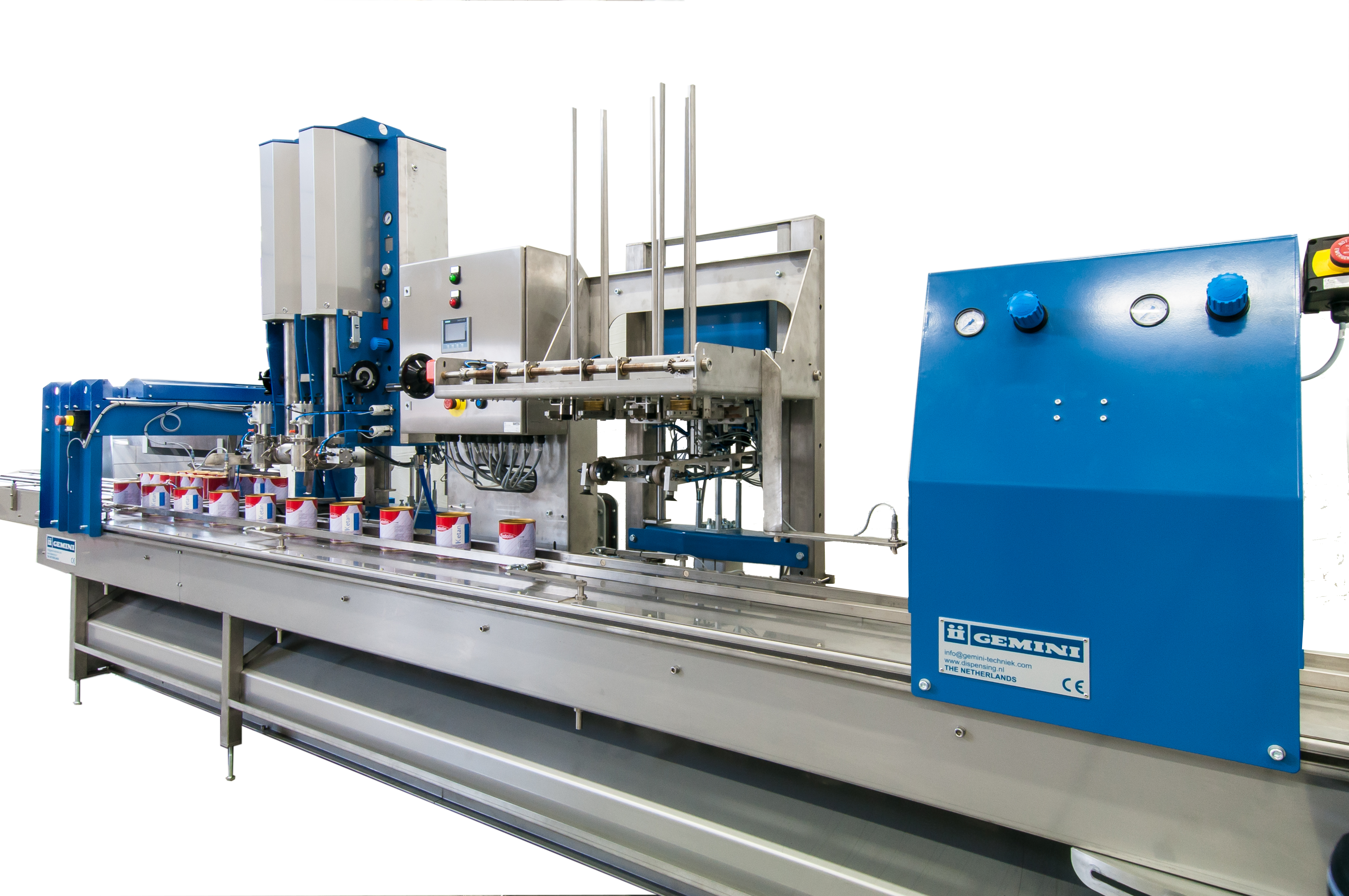

GemiFill C

FULLY AUTOMATIC VOLUMETRIC FILLING MACHINES

TYPICAL FEATURES

- Fully pneumatic operated (explosion-proof in accordance with ATEX).

- Self-priming and filling directly out of a drum/barrel or moveable vessel.

- Suitable for plastic and metal containers up to 20 ltr. (larger volumes upon request).

- Easy to clean by means of a removable filling cylinder and/or an automatic rinse cycle.

- Transport system with sinus curved drive (= slow start, fast transport).

- Volumetric filling with S-2½ / S-7½ / S-12½ or S-20 filling machine. (For detailed information: see the GemiFill S-model brochure).

- Quick width-adjustment (stepless) of the whole line.

- Easy to operate and very short installation/start-up time.

VOLUMETRIC FILLING METHOD

The filling machines are based on a vertical placed selfpriming dosage cylinder. A piston is vertically moving inside a cylinder. The stroke length and the diameter of the piston determine the fill volume. With a multiple stroke counter, larger fill volumes can be realised.

OPTIONAL SET-UP

The GemiFill C filling machine can be extended with the following options:

- Infeed conveyor/table.

- Lid placing device.

- Discharge roll conveyor.

- Check weigher.

- Hopper with maximum level control.

- Pump with (self-cleaning) filter.

- Multi-head filling possible.

- Partially PLC controlled.

Other options upon request.

The lid closing device is suitable for press lids, crimping lids and spring latch lids.