Custom Dispensing Systems Designed for Your Production Needs

In modern production environments, precision dispensing is more important than ever. Whether you're working in the paint, coatings, ink, chemicals, or food industry, accurate dosing of liquids or semi-liquids can make or break your process. From improving product consistency to reducing waste and boosting efficiency, a good dispensing system is key to staying competitive.

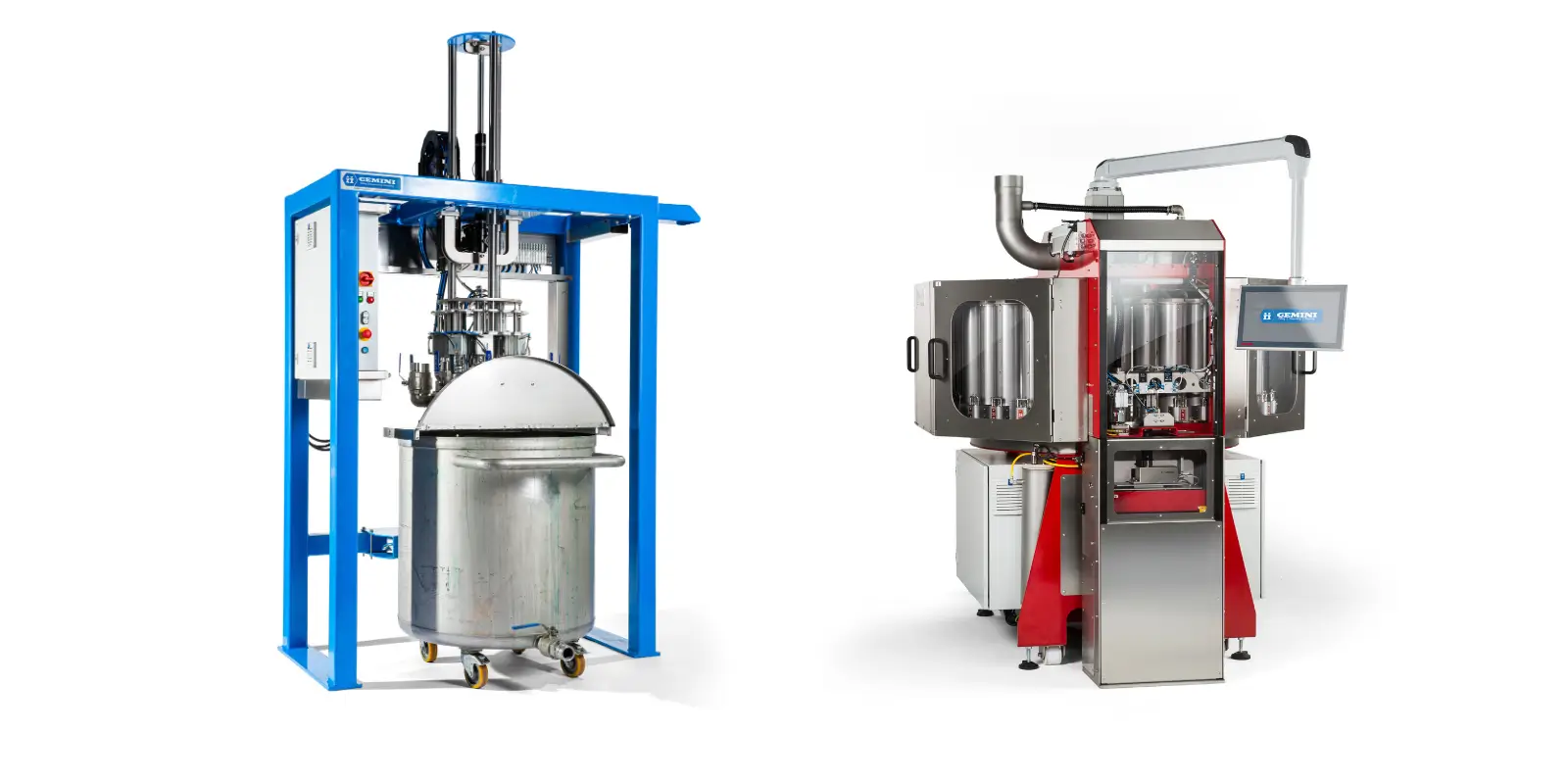

At Gemini Techniek, we design and build custom dispensing systems that are engineered to fit your specific needs. No matter how complex or unique your setup may be.

What is Dispensing?

Let’s start with the basics.

Dispensing refers to the controlled delivery of a specific amount of liquid. This can be done in many ways, depending on the industry and product. In industrial environments, dispensing is often automated to guarantee accuracy, reduce material loss, and speed up the process.

Think of:

- Filling paint into cans

- Adding ingredients to a food batch

- Mixing chemicals in precise ratios

- Tinting inks directly in containers

Each application has its own challenges. Viscosity, temperature, safety requirements, container types, and dosing volumes all play a role in the best dispensing strategy.

That’s why standard, off-the-shelf solutions often fall short. Every production line is different and that’s where Gemini Techniek comes in.

Custom-Built Dispensing Systems from Gemini Techniek

At Gemini Techniek, we don’t believe in one-size-fits-all. We specialize in custom-built dispensing machines tailored to your product, environment, and operational goals.

From small-scale laboratory setups to large-scale industrial production lines, we design our systems around your workflow. Not the other way around. Our goal is to make your process faster, cleaner, and more efficient from day one.

Our Dispensing Methods

We offer two main dispensing solutions, each designed to suit different types of operations:

Batch Dispensing

Batch dispensing is ideal when precise pre-mixing is needed. The system doses each component into a central mixing tank in controlled amounts. It ensures that every batch is consistent, repeatable, and accurate.

This method is great for:

- Paint and coatings manufacturing

- Chemical blending

- Food ingredient mixing

- Ink production

Benefits:

- High level of control and repeatability

- Works alongside your existing filling equipment

- Ideal for recipes with multiple components

In-Can Tinting

In-can tinting is all about flexibility. Instead of pre-mixing everything in a central tank, this method doses colorants or additives directly into the final container.

It’s a perfect solution for:

- Point-of-sale tinting

- Small batch runs

- Production environments with frequent changeovers

Benefits:

- Faster turnaround times

- Less cleaning required

- Minimal product waste

- Great for custom orders and on-demand production

Why Choose Gemini Techniek?

Are you looking for a custom dosing or filling machine that fits seamlessly into your production process?

At Gemini Techniek, we don’t offer off-the-shelf machines. Instead, we design and build tailor-made dosing systems based on your specific requirements. Whether you're working with thick pastes, corrosive substances, or sensitive food-grade ingredients.

Our industrial dosing machines are known for their precision and efficiency. The result: reduced material waste, lower production costs, and consistent product quality. Thanks to their modular design, our systems easily scale with your growing production demands.

Durability is key. We use only high-quality materials and components to ensure long-term, reliable performance. Even in demanding industrial environments. Despite their advanced capabilities, our systems are intuitive and user-friendly, allowing for quick operator onboarding and smooth integration into existing production lines.

Whether you're producing small, customized batches or require a scalable solution for high-volume operations, a dosing system from Gemini Techniek helps you maximize efficiency, flexibility, and product consistency across your process.

Dispensing for Every Industry

We serve a wide range of industries, including:

- Paint & Coatings

- Printing Inks

- Chemicals

- Food Ingredients

- Laboratories and R&D

Each industry has its own challenges, from hygiene regulations in food to solvent safety in chemical environments. We take all of that into account during the design phase, so you get a system that truly fits your needs.

Gemini: Your Long-Term Technology Partner

Gemini Techniek is more than just a machine supplier. We’re your engineering partner. We work closely with you from the first idea to the final installation and beyond.

Our team helps you:

- Define the best solution for your process

- Build a system that matches your needs

- Maintain and optimize your equipment for years to come

We’re proud to be a long-term partner for customers across the globe. From local companies to international enterprises, our mission is always the same: helping you produce smarter, faster, and better.

Let’s Talk About Your Process

Looking for a dispensing solution that truly fits your production process?

Get in touch with us. Our engineers are happy to explore the possibilities with you. Whether you're upgrading an existing line or developing a completely new system.

Use the button below to schedule a no-obligation consultation, visit our dispensing solutions page for more information, or download one of our brochures.