Dispensing Machines

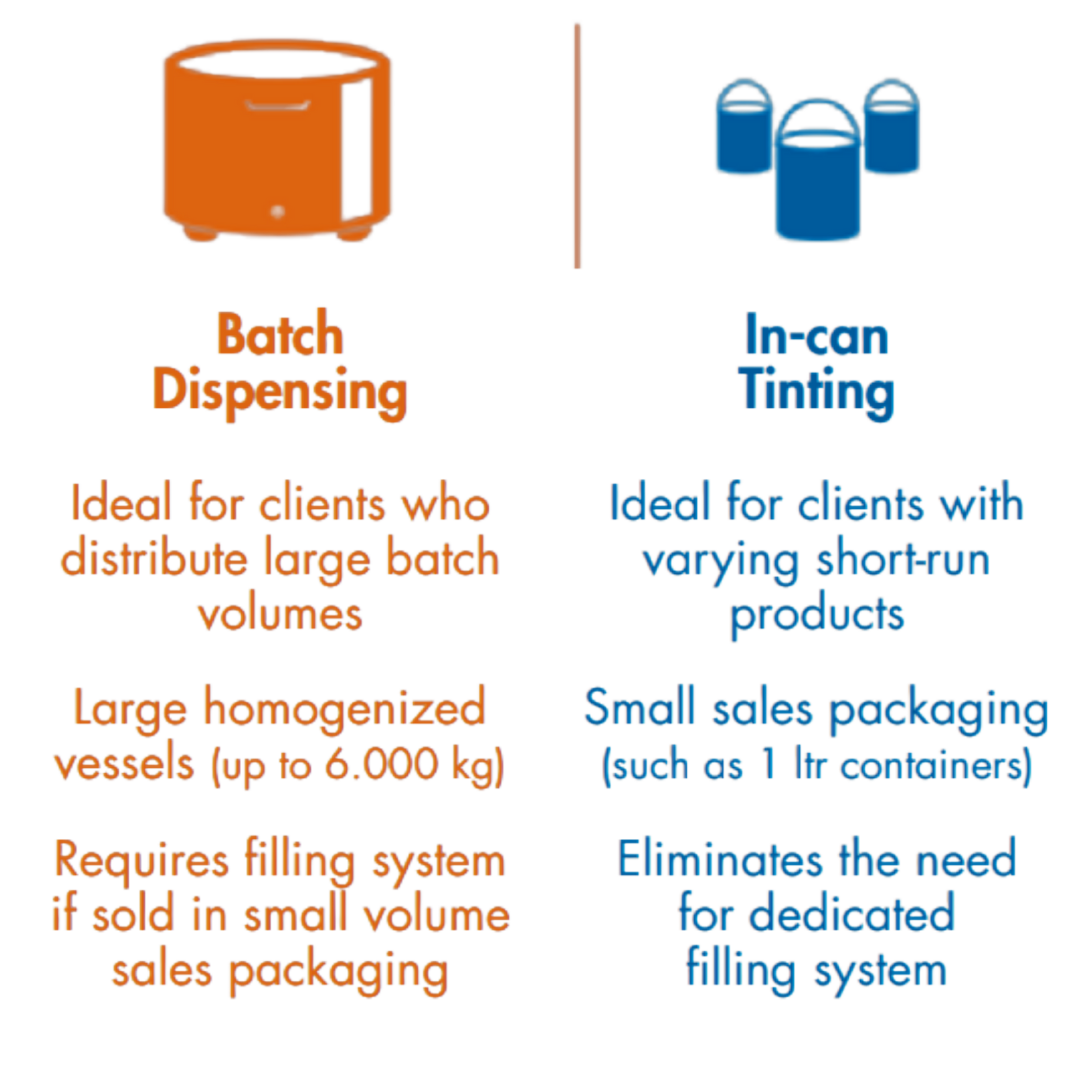

Paint dispensing (often referred to as blending, dosing or tinting) can be divided into two production methods: 'In-can'-tinting or Batch dispensing.

Batch Dispensing

Batch Dispensing means that the various individual components are dispensed into large batches, mixed and connected to a filling system to be accurately placed into the final sales packaging. Batch dispensing is a great solution for users who already have a filling system or prefer larger homogenized dispensed batches for their material.

In-can Tinting

In-can Tinting means that various individual components are dispensed directly into the sales packaging. This method bypasses the need to produce a large batch or for a dedicated filling system. It also eliminates the need for regularly cleaning the mixing vessel(s) and filling system after each product change.

Our Machines

Dispensing Applications

Gemini Techniek produces customer-specific dispensing applications for various industries.

The industries for which Gemini Techniek supplies the dispensing applications are:

Paint & Coatings Industry

Gemini manufactures custom made dispensing machines for a wide range of applications in the paint and coatings industry that can combine product storage, dispensing, logistic systems and mixing / shaking. We have developed some typical dispensing machines (ColorKing RT, FlexoKing CD, FlexoKing FT) that may suit your specific needs, but we also manufacture more conventional systems. All our dispensing machines are able to produce large batches and/or small batches in the range between approx. 1 kg. up to 3.000 kg.

We can dispense paints, coatings, base materials and additives all on one weighing scale or on multiple weighing scales to achieve a higher output. Gemini systems are mainly used “in-plant”, but are also suitable for end users. Due to our long term experience in the paint & coatings industry, we have knowledge of dispensing very low viscosity products as well as high viscosity products.

Chemicals Industry

The chemical industry is similar to the paint & coatings industry. Recipe based dispensing of several components into a container. The chemical industry however may require higher safety measures. Keys or special tools, which are supplied for limiting access to areas or functions will provide a safe workplace.

Ink Industry

The ink industry requires the same dispensing technology as the paint & coatings industry. Especially inks that are being used for flexographic and gravure printing methods can be dispensed with the same dispensing machines as used in the paint & coatings industry. Ink manufacturers very often require “in-plant” dispensing machines to produce large batches of ink. At the same time, these ink manufacturers can recommend smaller dispensing machines to their customers for preparing small batches that have to be added to the printers. Gemini offers “in-plant” ink dispensing machines as well as more cost-effective smaller dispensing machines (e.g. FlexoKing CD) for the end-users.

Wallpaper & floor covering Industry

The wallpaper & floorcovering industry has completely different requirements due to the products that are being used (e.g. PVC plastisols & pigment pastes). For this industry we have developed the Gemini WPD system that combines product storage, automatic transport of empty tubs, dispensing and mixing. Especially the mixing unit is unique in it’s kind. It has an automatic viscosity control system that has the ability to achieve the desired viscosity fully automatic. Gemini has successfully applied its dispensing / mixing technology in this industry.

Adhesives and sealants Industry

The adhesives and sealants industry is similar/close to the paint & coatings industry. Recipe-based dispensing of several components into a container. All our dispensing machines are able to produce large batches and/or small batches in the range between approx. 1 kg up to 3.000 kg.

Explosion proof

The dispensing machines can be executed in explosion proof according to ATEX in category 1 / 2/ 3. It can also be executed in Class 1 Division 1 (or 2). Gemini can provide their machine in the right category according to the environment of the customer.